Pre-treatment

We will place the grey fabric in the pre-treatment area for 24 hours first, allowing it to retract naturally, then go through the related process to make the grey fabric ready for dyeing.

Please send us your message, we will reply within 24 hours.

As an OEM manufacturer of knit fabrics and woven fabrics, King Fabric has the ability to manage all aspects of our production. This means better quality control, consistent dyeing/printing effects, optimal timeframe and re-orderability.

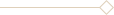

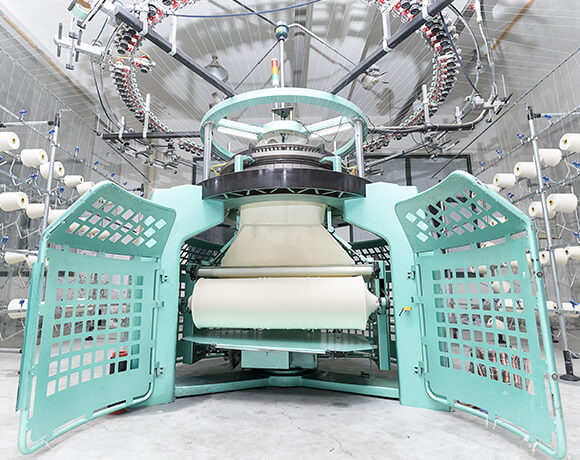

Equipped with 50 knitting circular machines, our factory can produce around 750 tons of fabrics monthly.

These machines are able to produce different kinds of fabrics including single jersey fabric, Ponte fabric, scuba fabric, jacquard fabric, loose knit fabric, and the rest.

We will select only the high-quality and eco-friendly yarns from branded suppliers such as Shenghong, and we will also check for broken-end yarns during production. Regular cleaning of the knitting machines is required to avoid yarn knots so that the grey fabrics can be smoothly knitted without defects.

The finished grey fabric will be rolled and put under inspection. During this process we will check the length, width, weight, and other specifications of the grey fabric to ensure it meets the production standard.

Our experienced fabric inspectors will closely review whether there are holes, broken yarns, missing stitches or any other problems, making sure the grey fabric is ready for the next processing step.

To provide you with the rich, fresh and vibrant color effects of the fabric, we will test and match our eco-friendly dyes a hundred times just to give you the exact color you need.

1

1

We will place the grey fabric in the pre-treatment area for 24 hours first, allowing it to retract naturally, then go through the related process to make the grey fabric ready for dyeing.

2

2

We have professional color-matching systems and dyeing techniques to ensure the color accuracy of the fabrics. Simply provide us with Pantone color code or color samples, and we will dye the requested colors for you.

3

3

We strictly control the drying time and the fabric amount in the process, and carefully place the fabrics so that they do not squeeze each other during drying, and thus lessening the chance of defects occurrence.

4

4

We adjust the width, weight and shrinkage of the fabric according to the client's needs, and use environmentally friendly chemicals to control the touch feel and functionalities of the fabric.

Just like adding icing on the cake, we need printings on our fabrics. Our expert printing process can make your fabric more vital and special.

Making the fabric ready to be printed on.

Various printing techniques give your fabric different patterns and visual effects.

We use the steaming process to fix the dyes in the fabrics.

This process will wash out the dirt, chemicals and excess dyes. This is also a way to adjust the pH value of the fabrics.

Adjusting width, weight, shrinkage, functionality and other specifics in accordance with the order details.

We are familiar with the testing standards of various countries and regions, and adopt the American standard four-point system to score the products.

From yarns to the final rolls of fabric, we have a series of strict quality control procedures to maintain our production standard. Each meter of the fabric will be inspected before shipment.