Knit Synthetic fleece is little connected to its natural counterpart that is made from wool. This fleece, also known as polyester fleece is a manufactured fabric made from polyester, an extruded polymer fiber.

This fleece fabric was first developed and excel the qualities of wool. The novel fabric was patent-free, becoming quickly and widely utilized in a variety of designs worldwide. Initially, this polyester fleece fabric was adopted by outdoor enthusiasts who appreciated this fabric as a lightweight, comfortable and flexible alternative to woolen layers, especially its affordable price. It soon gained widespread appeal, transitioning from being perceived as a technical fabric to a household staple, as designers and clothing manufacturers found new and mainstream ways of exploiting its properties.

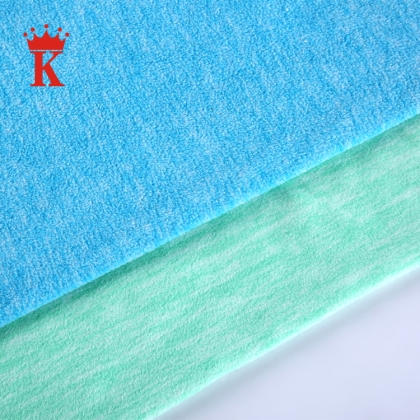

The fabric is soft-napped and known for it’s soft, felt–like or fuzzy texture. Though much lighter than wool, polyester fleece fabric possesses a pile that retains heat effectively and has a similar, wool-like warmth and softness. The fleece tends to be anti-pilling, meaning that the fabric is less likely to develop bobbles or bumps with wear over time.

The addition of cotton or other fibers as well as differences in manufacturing techniques can produce a wide variety of fleece fabrics, making it easy for a designer to source the ideal fleece fabric for a product. The qualities of this fabric, as well as its durable and water-resistant properties, making it an incredibly versatile choice for producing a variety of clothing and household items.

Key Characteristics of Fleece Fabric

- Two sides brushed fleece: This feature contributes to the heat retaining properties of the fabric. Both side brushed fleece provides space for air pockets between threads.

- Does not fray:Which makes fleece an ideal fabric for the creation of blankets, scarves and other no-sew products.

- Varying thicknesses available: This fleece fabrics can be rated according to the thickness which varies from microfleece fabric, through 100-500gsm which is the thickest fleece.

- Water resistance/waterproof: The polyester fibers that make up synthetic fleece are inherently water resistant. These fleece fabrics typically hold less than one percent of its weight in moisture. We can also make durable water proof function finish for outdoor products use.

- Breathable: Though warm, moisture and air are able to move through this fabric, especially the thinner and more flexible fleece variants.

- Lightweight: Polyester Fleece garments are much lighter than equivalent clothing created using natural wool fibers.

- Machine washable: Maintenance of polyester fleece fibers is simple, as this fabric washes well without significant shrinkage warping or pilling. They do not hold large amounts of moisture these fabrics dry quickly.

- Holds its shape well:This property adds greatly to the durability of garments made from polyester fleece.

Usage of fleece fabric

Garment fashion designer or crafts enthusiasts are probably best placed to describe the full range of products that can be made with polyester fleece fabric. As it is low maintenance and workable, fleece has surged in popularity, and it is widely used in home sewing projects.

This knitted fabric has a broad range of uses including clothing, such as jackets, sweaters, mittens, scarves and baby clothes. It can also be used to create blankets cheaply and to line clothing. And it is considered a good choice for a variety of pet bedding also. It is the stand-in of choice for wool.

Fleece fabric Manufacturing steps

- Polyester material: The manufacture of fleece fabric starts with creating its component fiber – polyester. This polymer, originally known under the proprietary name PET is made by reacting an acid with ethylene glycol, creating a polymer which is extruded through a special disk with holes called a spinnaret at high temperature. The fibers produced are then made to a filament.

Polyester can also be manufactured from recycled plastic PET bottles, which are chipped and melted to form fiber, which is called as Recycled polyester filament. This material needs to be verified by GRS certification. - Knitting: Use material to knit greige fabric, machines including warp or weft circular machine, these two machines will produce a variety of a different kind of fabric structure.

- Dyeing: Use eco-friendly dyestuff to dye any colorful color.

- Napping/brushing: The knitted fabric is passed through a brushing machine. This specialized machine raises the fibers in the fabric using numerous raising rollers. Besides, The fabric may be additionally brushed for addition to heat-holding capacity or rich fleece.

- Shearing: Another specialized machine cuts the raised fibers, creating the fleece’s familiar, fluffy pile.

- Heat-Finishing: Make fabric structure and weight fixed after high temperature. the fleece fabric may be finished with specialized finishing; coating(WR, Light blocking, Flame retardant), bonding, printing, etc.

- Inspection and package: Professional knitted fabric manufacturer will do this most important step before shipment.

Other types of knitted fleece fabric

Aside from the original polyester polar fleece fabric, there is the range of specific fleece fabrics each with their own properties and uses.

Cotton or blend fleece

Use cotton instead of polyester, or is blended with polyester to create a blended fleece. It can be produced from two to three yarn and brushed to make a characteristic deep fleece pile. This fabric is readily dyed and particularly comfortable and luxurious and is often called sweatshirt or hoody fleece after its main use.

Lycra spandex fleece

This fleece offers thermal properties alongside a 4-way stretch, to create an incredibly versatile fabric that offers superior comfort and movement. Ideal for sportswere, this stretch fleece is typically made from polyester with a percentage of spandex. Many forms have a knit jersey face with brushed fleece underside.

Micro fleece fabric

This polyester based fleece is a lightweight fabric that offers excellent thermal performance and quite soft handfeel. Due to its light weight breathable quality, it is often used as a thermal lining with other fabrics. It is the thinnest fleece available and so is highly flexible with weight.

Blizzard fleece

This is a particularly thick form of polar fleece which is highly sought after for winter gear and blankets. Its thick pile retains heat and it is so dense that its ends may not need finishing after cutting.

French terry fleece

This is a knitted fabric with an outer layer that is a smooth soft jersey with a light fleece underside. It is similar to the sweatshirt fabric as described above but less thick. It can be also made from 3 different yarn to create a distinctively textured appearance of the fleece. It is available in a variety of weights and colors.

Sherpa fleece

This fleece is typically made from polyester or acrylic or a blend of both fibers. It is manufactured to mimic a sheep’s fleece with generous naps and a deep pile. Sherpa fleece fabric is thick and extremely warm. The outside layer is the distinctive sherpa fleece, while the underside is a uniform smooth knit. Weights are up to 500gsm.

Cuddle/Minky/Flannel fleece fabric

A niche fleece fabric used for plush toys and similar projects. Also known as minky fabric, it is particularly soft. The fabric is one-side or double side fleece layer brushed for a luxurious, cozy finish.

Innovations in fleece fabric

Use of recycled plastic to create fleece clothing is on the rise. Integration of biodegradable fibers into fleece blends is also achievable. Bamboo and cotton blended fleece are particularly sought after and cotton and wool blends are being developed to create a natural alternative to the classic polar fleece.

Contact us to Source fleece fabric for your project

Your choice of fabric is critical to the success of your design. In working with fleece, you have a variety of options meaning it has never been easier to source the right solution for your project.

If you are looking for a fleece fabric manufacturer with expertise and a high-quality product we are on hand to provide entirely custom fabrics that can be integrated as part of your design. We manufacture a comprehensive range of fleece fabrics of varying weights and designs.

We can provide you with the minimum and maximum quantities of your chosen fleece. Our lead times are prompt meaning that you can work with us to prepare your ideal production schedule. Prices are competitive without cutting back on quality and repeat orders are welcome.

Ask us to find out everything you need to know about your required fleece including printing designs, care of the fabric and correct thread and home or commercial sewing techniques for optimal performance of your choice of fleece.

Our company operates globally and provides a robust and reliable service for leading sportswear and clothing brands and designers. Fabric samples are available to show, ensure that you acquire the right material, and source your ideal fabric successfully. Contact our personable team to let us know your exacting requirements, which we should be sure to not only meet but exceed.